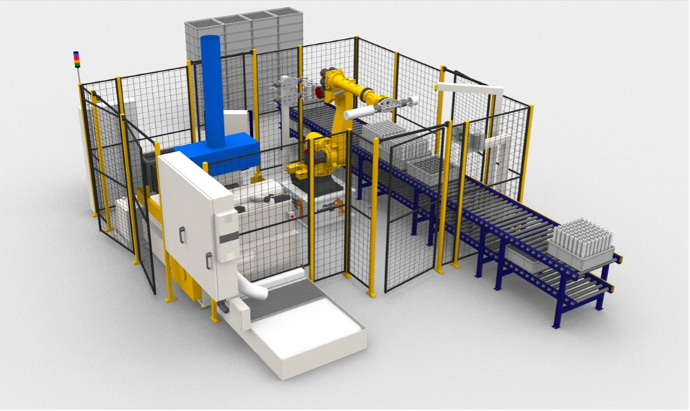

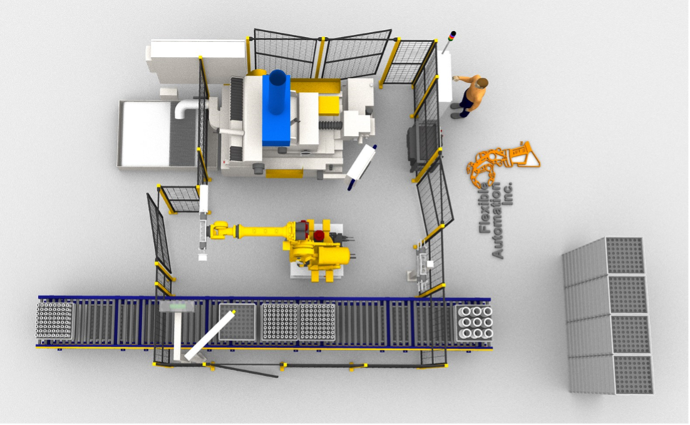

Robotic Cells

Robotic cells are a hallmark automation solution capable of performing more complex tasks such as assembly, leak detection, welding, and testing, when compared to traditional automated machines. At Robot Industries, we specialize in designing and creating personalized robotic cells for a variety of applications based on our customers’ needs and requirements while optimizing costs and increasing performance.

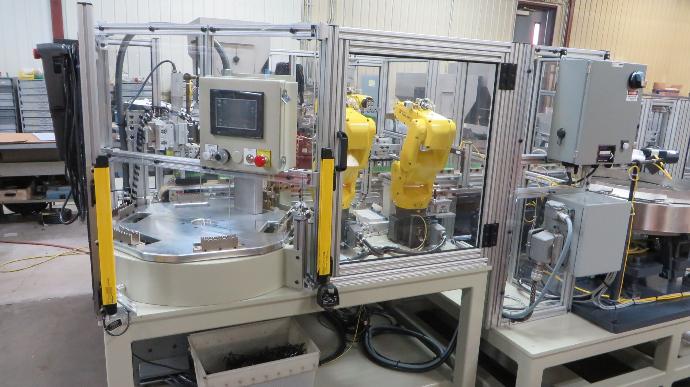

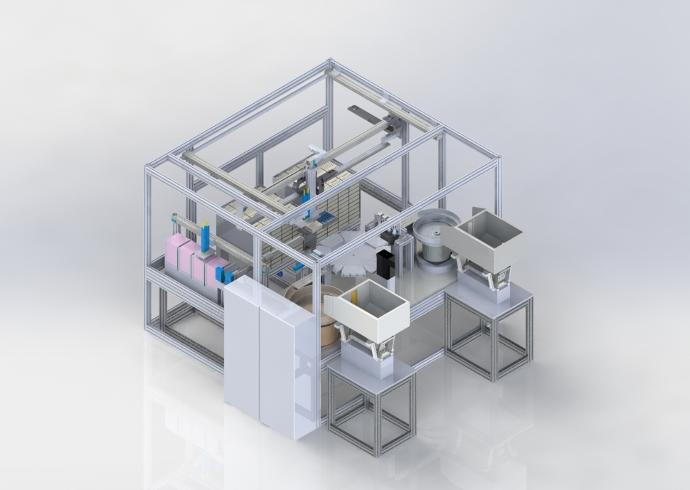

What Are Robotic Cells?

Robotic cells contain components that are needed for a robot, or multiple robots, to perform tasks on an assembly line. These tools may include sensors, end effectors, tooling, part feeding mechanisms, safeguards, and more. Instead of spreading out each step at different stations, robotic cell setups perform the entirety of a process in the cell.

At their core, assembly robotic cells manipulate components into a specific position or into an assembly for future packaging, shipping, or use. Along with this functionality, RobotIndustries can design robotic cells that take on finishing processes such as:

- Applying paints, adhesives, or sealing materials to newly manufactured parts: Not only does the introduction of automated finishing result in more consistent appearance, but it also keeps workers away from the potentially hazardous chemicals.

- Applying staples and cable ties: Robots can apply cable ties to cable harnesses or gasoline tubing. They can also apply staples for automotive heat shield assembly into carpet or interior coverings.

- Transporting items: Robotic cells can be outfitted with automated equipment to note when an assembly task has been completed and move the assembly to the next station in the industrial process.

Why Use Robotic Cells?

Automation is an advantageous addition to almost any industrial process because it adds speed, increases worker safety, and reduces the risk of human error or inconsistency.

Robotic cells are even more beneficial because they can handle complex tasks and manage both the assembly stage in its entirety and the transition to the next stage. Some of the specific benefits of robotic cells include the following:

Efficiency

Automated processes can perform longer without increasing the likelihood of errors or inconsistent work quality. Even when automated assembly tasks take longer than manual processes, which is rare, the increased duration results in more assembled products.

Consistency

Robotic cells follow set instructions and specifications to perform tasks and ensure the work meets the set standards. This results in more consistent output from start to finish, even as assembly tasks become more complex. Using robotic cells for finishing tasks, such as painting, results in a more consistent product.

Savings

Robotic cells increase the cost-efficiency of assembly projects. Automated tools work longer and faster than manual processes and don’t require wages, benefits, or other auxiliary costs. As technology continues to increase, creating, maintaining, and repairing robotic systems becomes more affordable.

To install this Web App in your iPhone/iPad press

![]() and then Add to Home Screen.

and then Add to Home Screen.