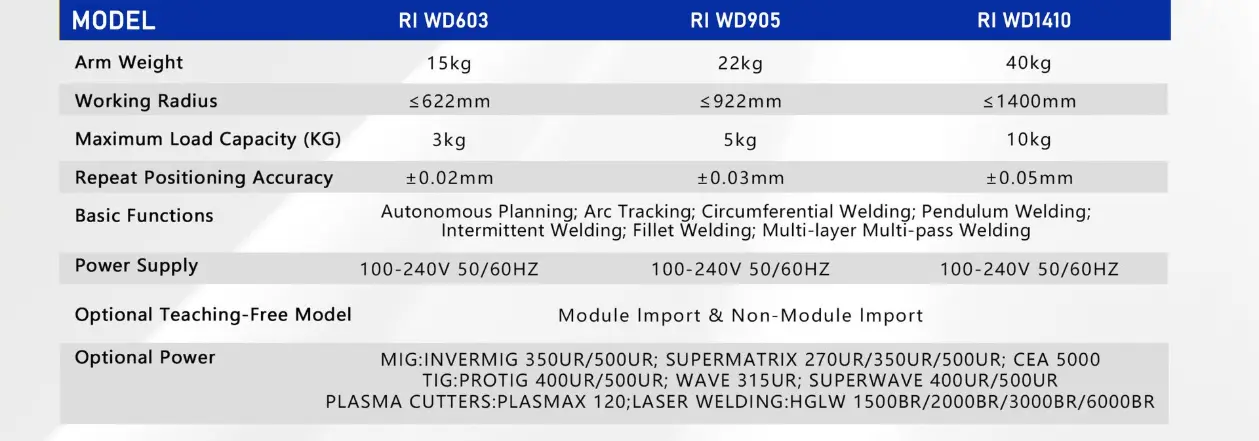

RI WD1410-500A MIG Collaborative welding station

RI Portable Welding Cobot Cell

The RI Welding Cobot Cell enables flexible, high-efficiency welding. It can be easily repositioned within the work area, ready for the next task.

It supports various welding techniques, including electric arc, TIG, MIG, laser, plasma, ultrasonic, spot welding, and brazing.

RI WELDING COBOT CELL

- Master welding system controller

- 6-Axis cobot

- Portable permanent magnet base

- Specialized welding torch

- Welding power supply

- Wire feeder (with 5 meters cable)

- Specialized controller board

APPLICATIONS

-

Branch welding line of steel structure light steel production line

-

Laminated welding for bridge steel structure

-

All kinds of application scene, multi welding procedure

Friendly interface, Simple programming, Operation with high efficiency

The RI WD collaborative robots offer a user-friendly interface and an optimized operating process, making them easy to use without requiring professional programming skills. This significantly enhances work efficiency and provides robust support for professional welding operations.

Precises welding by manual positioning, multi-welding is under control

Equipped with advanced visual manual positioning technology, the RI WD Collaborative welding station accurately locks onto the welding area and simulates the welding path in real time, streamlining preparation procedures. Its human-machine collaboration mode simplifies complex multi-welding tasks, ensuring precision and ease of use.

Overcoming welding issues at special position

Designed to tackle welding challenges in specialized positions, the RI WD Collaborative welding station excels in operations requiring deep access to narrow spaces, seamless welding on intricate curved surfaces, and high-precision welding at complex angles.

Integrated design, flexible application

The highly integrated design features a compact, elegant structure that optimizes space while enhancing machine stability and reliability. Its user-friendly maintenance reduces costs and ensures long-term, dependable performance for professional welding applications.

Customize welding technology with perfect welding seam

Operators can manually customize welding parameters, store additional beam settings, and adjust positioning for various welding requirements, including straight, corner, and diagonal welding. The system’s flexibility accommodates a wide range of welding applications across industries.

Widely compatibility to satisfied varied requirement

A comprehensive one-stop solution, the RI WD Collaborative welding station supports diverse industry needs with optional professional welding equipment for TIG, MIG, and laser welding.

Intelligent protection at any time

The system features a cutting-edge "intelligent sensing unit" equipped with advanced perception capabilities and certified safety mechanisms.

Utilizing integrated laser radar, infrared, and high-precision force sensors, it continuously monitors its environment, detecting potential collisions in real time. Upon encountering an obstacle, it autonomously adjusts its path through an automatic rebound mechanism and, in critical situations, executes an immediate stop to ensure safety.

Its innovative "automatic rebound" technology enables seamless trajectory correction to prevent collisions, while the "instant stop" function provides an added layer of protection by halting operations when necessary.

To install this Web App in your iPhone/iPad press

![]() and then Add to Home Screen.

and then Add to Home Screen.