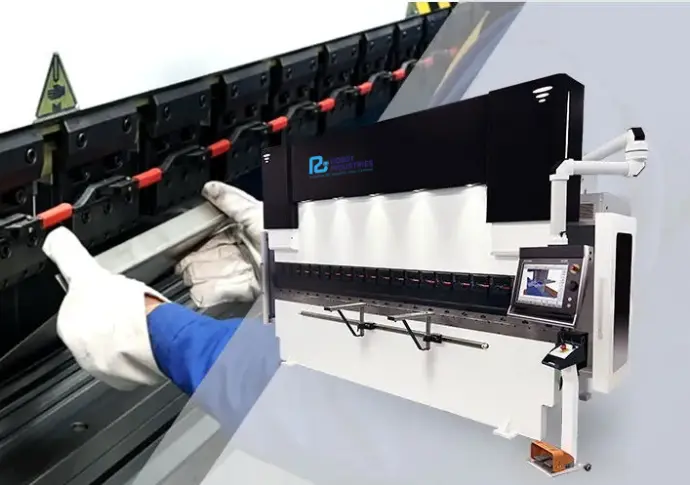

RI Electro-hydraulic Servo Bending Machine WE67K Series

RI Electro-hydraulic Servo Bending Machine WE67K Series

The RI Electro-Hydraulic Servo Bending Machine WE67K Series offers functionality comparable to the DA58T. Its fully automated navigation system streamlines the adjustment of backstops and rams, simplifying machine setup and significantly reducing commissioning time.

Axis configuration, I/O point settings, and auxiliary function parameters can be precisely customized to meet the specific requirements of each bending application.

The CNC press brake uses either standard or custom molds to bend cold metal sheets into parts with various geometric cross-sections. It's a metal forming machine specifically designed for processing cold-rolled sheet metal. The RI press brake is equipped with intelligent features, including a touchscreen controller and a crowning system, which simplify the bending process and significantly enhance overall efficiency.

INTUITIVE CONTROLLER

The user-friendly graphical touch controller gives full play to the bending performance of the machine.

SERVO-CONTROLLED HYDRAULIC SYSTEM

Hydraulic components are manufactured to a high standard to ensure excellent performance.

RIGID STRUCTURE

All HUSONE Series are designed and built utilizing a welded one-piece frame machined to guarantee machine precision.

LINEAR ENCODERS

High-precision linear encoders provide high positioning accuracy and repeat-ability.

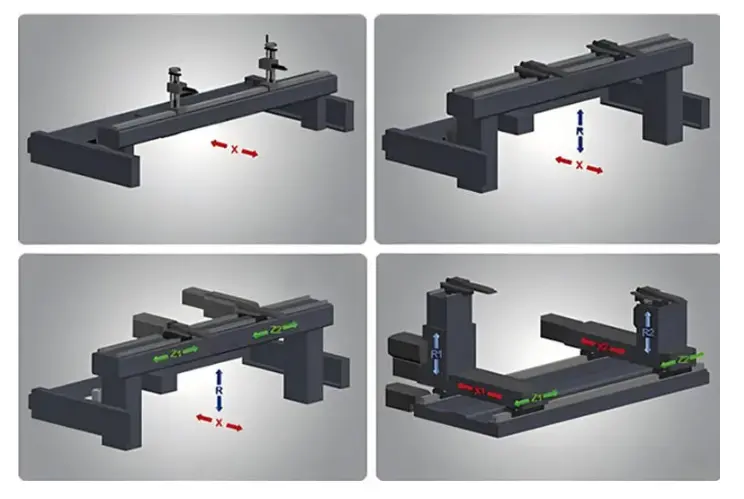

BACK GAUGE

The newly designed back gauge is a robust construction featuring 2-axis or 4-axis configurations for greater flexibility and increased productivity.

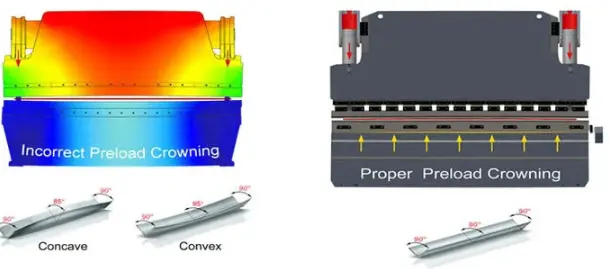

CNC CROWNING

CNC mechanical crowning. High precision, improving the precision of bending angle and linearity.

Crowning System

During the bending process, stress can cause deformation in both the ram and worktable. The crowning system compensates for this ram deformation, significantly improving the press brake's precision. This system is particularly useful for manufacturing high-precision products such as stainless steel components.

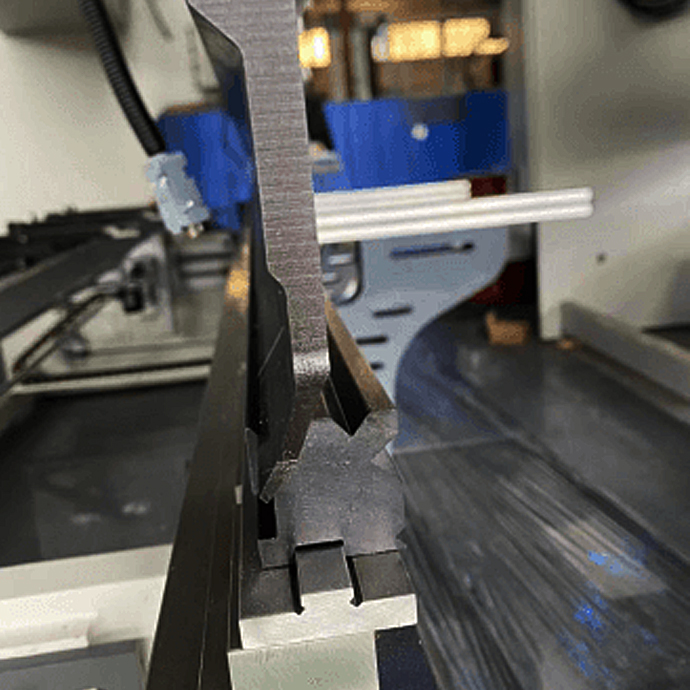

One-Key Release Fast Clamp

This system allows quick and convenient attachment and removal of the upper punch, saving time and simplifying your workflow.

Press Brake Tooling

Our press brake tooling is crafted from 40CrMo material, hardened up to 52 HRC, ensuring extended die service life.

Laser Protection

This safety feature is an excellent addition to any machine. It significantly reduces operational risks when employees work with the press brake.

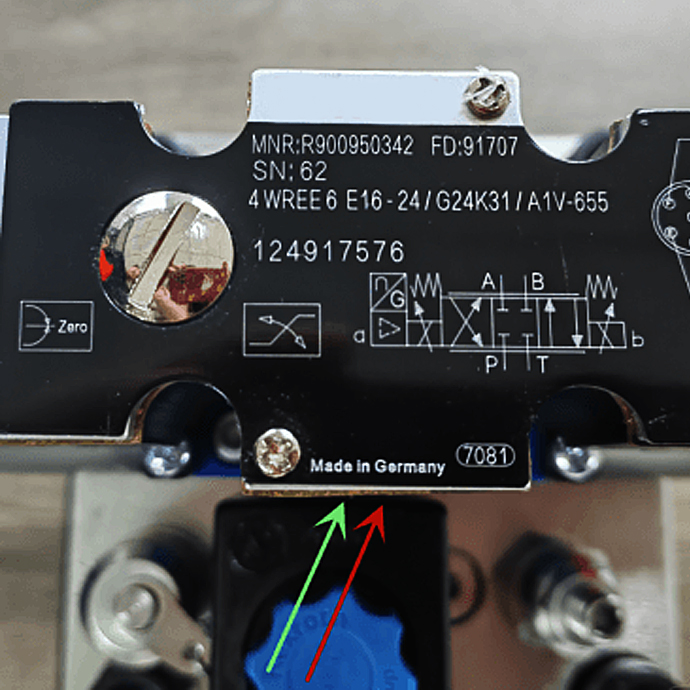

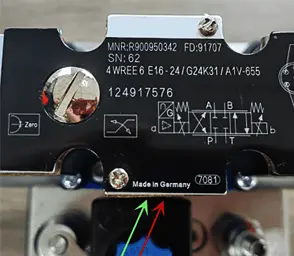

Hydraulic Valves

Safe, efficient, and built with premium quality.

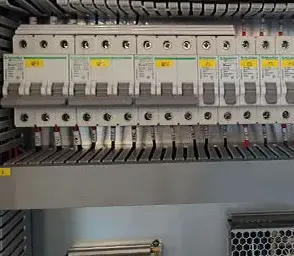

Schneider Electrical System

Our press brakes utilize Schneider electrical components. These high-quality parts ensure stable machine performance even with fluctuating power supply, and replacement parts are readily available worldwide.

CNC Back Gauge

RI press brakes are equipped with a CNC back gauge featuring a solid structure to ensure optimal repeatability and high-precision axis positioning.

Standard Machine configuration:

- Rexroth hydraulic valve block

- Rear stop servo motor: Yaskawa

To install this Web App in your iPhone/iPad press

![]() and then Add to Home Screen.

and then Add to Home Screen.