MAVITEX x Robot Industries

THE CLIENT

Mavitex, founded in 2007, is a well-established construction company based in Romania. Known for delivering end-to-end services, ranging from design and consultancy to full-scale execution, Mavitex has built a strong reputation for quality and efficiency in executing complex construction projects.

With a focus on industrial buildings, Mavitex works both at its facilities and on client sites, taking on large-scale welding operations that demand precision, speed, and adaptability.

THE CHALLENGE

Mavitex regularly executes welding tasks for industrial halls, where components are large, heavy, and not always easily accessible.

Key pain points included:

● The need for high-quality, uniform welds, even in elevated or hard-to-reach areas

● Manual welding on-site and in the warehouse, which was time-consuming and prone to inconsistencies

● Operator fatigue and safety concerns, especially for repetitive tasks or work at height

● Limited flexibility when adapting to different client sites and structure types

The challenge was clear: how to maintain welding quality and efficiency, across locations, without adding complexity or risk.

THE SOLUTION

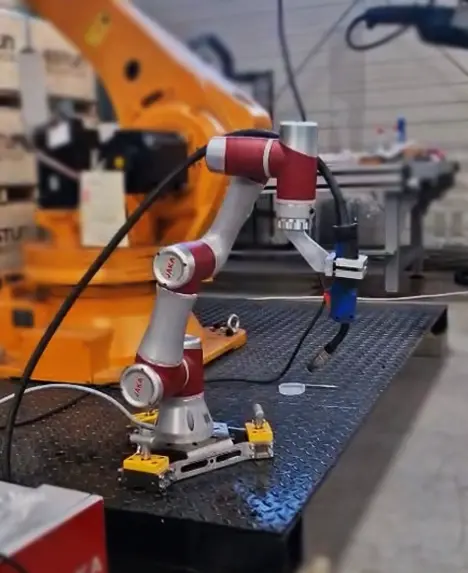

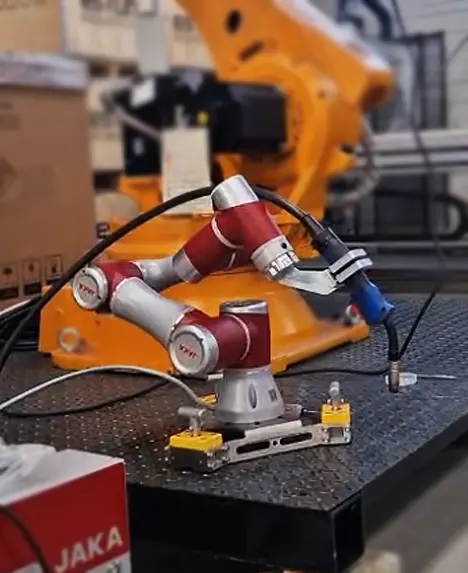

To help Mavitex gain control over their welding processes, both in-house and on-site, Robot Industries implemented a ZU 3 collaborative welding robot: a compact, mobile, and highly flexible solution designed for real construction environments. This robotic system was selected for its ability to deliver precision welding, mobility, and ease of integration—all in one.

Why the ZU 3 Cobot?

● It has a 6-axis robotic arm, which means multi-directional movement and precise articulation, enabling smooth, controlled weld paths even on complex structural elements.

● It works a radius of 626 mm, providing enough reach for large components while maintaining a small physical footprint, perfect for tight spaces and modular setups.

● It has a payload capacity of 3 kg and supports a range of welding torches and lightweight tools, ensuring versatility across different project needs.

● The robot can be mounted instantly on any metal surface: vertical, horizontal, or at an angle, without any fixed installation, frames, or mounting systems. This feature makes it ideal for mobile welding operations, including at-height and remote job sites.

Thanks to its portability and plug-and-play setup, the ZU 3 robot became a flexible asset for the Mavitex team, being easily moved between their fabrication facility and various construction sites.

THE RESULTS

The integration of the ZU 3 collaborative welding robot brought immediate and measurable improvements to Mavitex’s welding processes.

● Improved welding precision and consistency: The automated arm ensured that each weld was applied with uniform force, position, and timing and it eliminated variations caused by fatigue or manual adjustments. This led to cleaner, more consistent welds that met both the structural and aesthetic standards required in industrial construction.

● Reduced execution time and faster project delivery: The ZU 3 optimized the welding workflow by significantly reducing the time needed for repetitive or extended weld paths. By standardizing weld cycles, the robot helped the team finish tasks quicker and more efficiently, especially on large components that typically required long manual sessions.

● Maximum flexibility across job sites: Thanks to the magnetic base, the ZU 3 could be mounted and operated on various metallic surfaces, whether flat, angled, or vertical, without additional installation structures. This gave Mavitex the freedom to deploy the robot in their workshop or directly on active construction sites, with minimal setup time and maximum mobility.

● Enhanced operator safety and better ergonomics: By taking over the physically demanding and high-risk portions of the job, especially welds performed at height or in awkward positions, the robot helped minimize operator strain. The team experienced fewer risks of repetitive strain injuries and benefited from a safer, more ergonomic working environment.

● More focus on skilled, high-value work: With the robot managing repetitive welding tasks, operators could shift their attention to process supervision, quality control, and other higher-value activities. This not only improved job satisfaction but also enhanced the overall efficiency of the production and installation.

For Mavitex, the ZU 3 robot wasn’t just a tool—it became part of the team. By adding mobile automation to their workflow, they gained speed, flexibility, and control—without compromising on safety or quality.

This solution shows how collaborative robots aren’t just for factories, they’re ready to support real-world construction sites too.

Want to explore how mobile robotics could work in your welding projects?

Let’s connect:

Start writing here...