In the Coming Years, Welding Companies Will Undergo a Technological Revolution

In

the coming years, welding companies will experience a technological revolution,

adopting complete automation and collaborative robots that will work alongside

humans, increasing efficiency and reducing risks. AI will optimize welding, while laser, microwave, and 3D welding enhance precision, speed, and efficiency.

Welding equipment will be more efficient and eco-friendly, using less energy and recyclable materials. AR/VR will enhance training, enabling welding in extreme environments like space.

The industry will evolve in a faster, more precise,

and more environmentally friendly direction, adapting to new technological and

environmental demands.

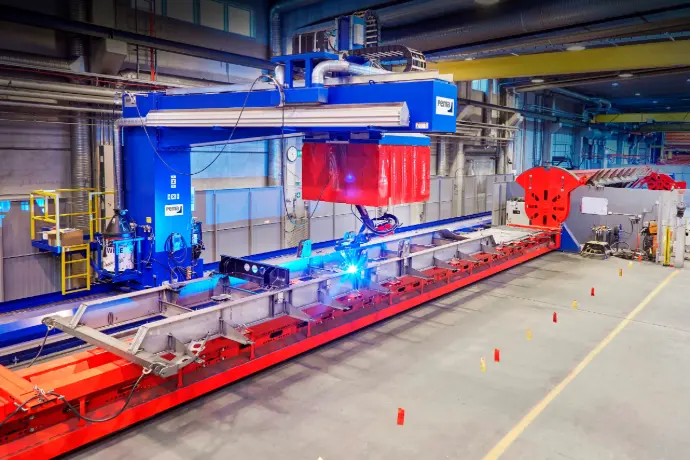

Few words about robotized welding solutions

Industrial welding robots excel in high-speed, high-volume production, ideal for automotive, aerospace, and heavy manufacturing. Operating in enclosed cells, they ensure efficiency and precision in mass production. In contrast, collaborative welding robots (cobots) work alongside humans, offering flexibility and safety features like force sensors. Ideal for SMEs, cobots enable cost-effective, adaptable small-batch manufacturing.

Advantages of Welding Automation

Welding automation offers numerous advantages, making it a preferred choice for industries requiring high precision, efficiency, and consistency. Here are some key benefits:

Increased Productivity

Faster operations with minimal downtime, Higher production rates due to reduced cycle times.

Better Efficiency & Reduced Downtime

Continuous operation with fewer interruptions, Precision in handling complex or repetitive tasks.

Improved Weld Quality & Consistency

Uniform

welds, fewer defects, and higher-quality joints, Reduces human errors.

Environmental

Benefits

Precise

control reduces waste and energy consumption, Supports sustainable

manufacturing goals.

Cost

Savings

Lower labor costs and reduced material waste, Minimizes need for rework and post-weld corrections.

Enhanced

Worker Safety

Reduces

exposure to hazards like fumes and radiation, Operators can control the process

remotely.

Robotic Welding Solutions by Robot Industries

Fields of Application for Welding Robots

Welding automation is widely used across various industries that require precision, efficiency, and high-volume production. Here are some key sectors where welding automation is a perfect fit:

- Steel Fabrication & Structural Engineering

- Automobile Manufacturing

- Pipeline & Heavy Equipment Manufacturing

- Aerospace & Shipbuilding

- Defense & Military Equipment

- Renewable Energy & Oil & Gas Manufacturing

You might also be interested in these robotic solutions

Applications of Welding Robots

To install this Web App in your iPhone/iPad press

![]() and then Add to Home Screen.

and then Add to Home Screen.