Client Overview

The company specializes in the manufacturing of metal products, including construction components, furniture, and accessories, with a strong focus on quality and product diversity.

It provides customized solutions and end-to-end services for a wide range of industries.

Initial Situation

The company was producing table legs and metal grates. Operations were carried out in a single shift, with one welder and one worker responsible for grinding.

In addition, the client was seeking to hire another employee to cope with upcoming large orders but was unable to find a qualified specialist despite extensive efforts. This limitation prevented the company from increasing efficiency and scaling production.

Solution Implemented

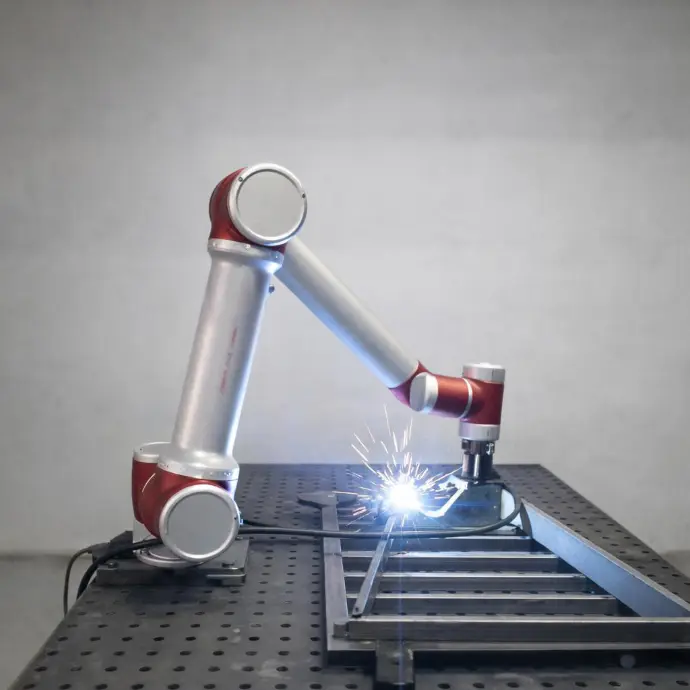

To address these challenges, we proposed the implementation of a JAKA ZU 12 collaborative robot, featuring a working radius of 1,327 mm and a 12 kg payload. The robot is equipped with six axes and operates using the client’s existing welding power source.

The primary objective of this solution was to support welders in their daily operations by assisting with large-volume orders, improving overall efficiency, and simultaneously reducing physical strain, fatigue, and risks associated with intensive manual labor.

Results

The implementation of the JAKA ZU 12 robot had a significant impact on welding process efficiency. Welders benefited from substantial support in handling high-volume orders, while welding time was reduced, leading to increased production output. Overall, the investment resulted in higher productivity and a safer working environment.

Automation and optimization of the client’s processes were achieved through the implementation of solutions provided by Robot Industries for PREDICT.

Welding Cobot – Home and Garden Furniture