CLIENT OVERVIEW:

Our client is a prominent company operating in the automotive, energy, and electronics sectors, specializing primarily in the production of plastic components. They faced challenges with the manual preparation of surfaces for coating/painting operations, which required precision and consistency.

INITIAL SITUATION:

The company relied on manual methods for preparing surfaces before coating/painting operations. This manual process was time-consuming, labor-intensive, and prone to inconsistencies, impacting productivity and quality.

SOLUTION IMPLEMENTED:

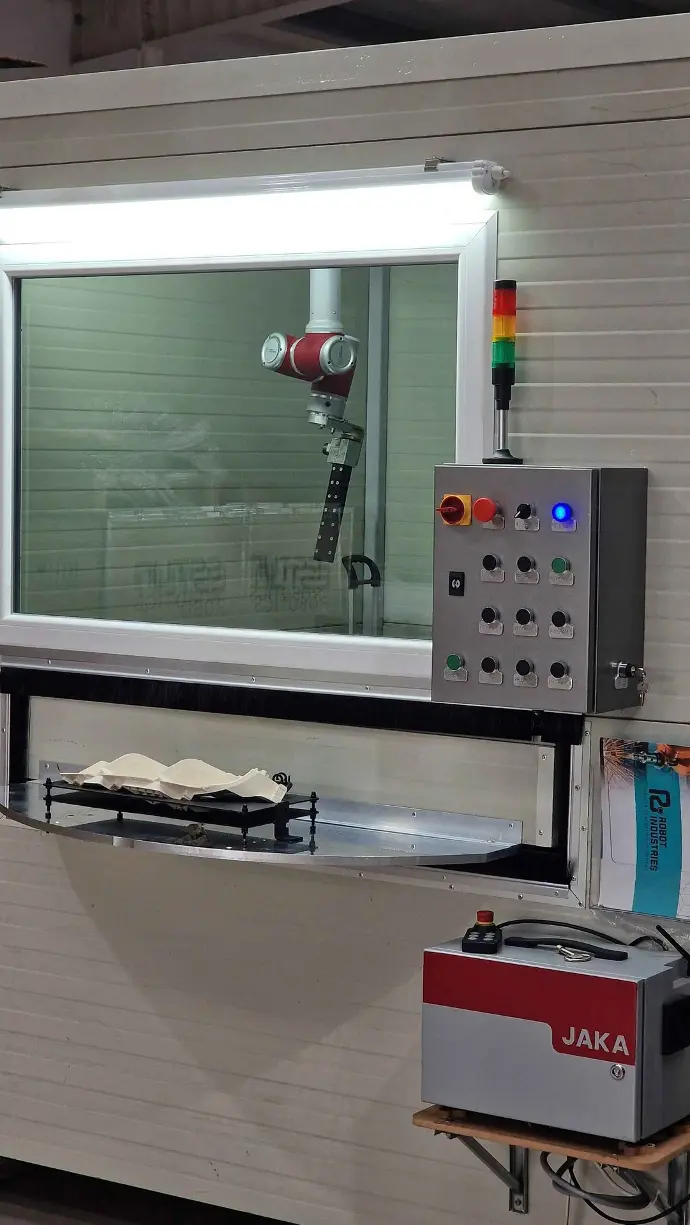

To address these challenges, the company opted for a turnkey solution

based on a Jaka robotic arm. The robotic cell was specifically designed for the

dry ice blasting of plastic components, providing an efficient and precise

method for surface preparation before coating/painting.

CLIENT OVERVIEW:

Our client is a prominent company operating in the automotive, energy, and electronics sectors, specializing primarily in the production of plastic components. They faced challenges with the manual preparation of surfaces for coating/painting operations, which required precision and consistency.

INITIAL SITUATION:

The company relied on manual methods for preparing surfaces before coating/painting operations. This manual process was time-consuming, labor-intensive, and prone to inconsistencies, impacting productivity and quality.

SOLUTION IMPLEMENTED:

To address these challenges, the company opted for a turnkey solution based on a Jaka robotic arm. The robotic cell was specifically designed for the dry ice blasting of plastic components, providing an efficient and precise method for surface preparation before coating/painting.

RESULTS:

The implementation of the robotic cell based on the Jaka robotic arm yielded significant results for the company:

- Increased productivity and quality stability: By leveraging the robotic arm for surface preparation, the company experienced a notable increase in productivity and stability in product quality. The automated process ensured consistent surface treatment, resulting in uniform coating/painting application and enhanced product aesthetics.

- Transfer of demanding and risky tasks: The Jaka robotic arm efficiently handled the demanding and risky task of surface preparation, reducing the reliance on manual labor. This allowed the company to reallocate personnel to tasks such as production preparation for the robotic cell, programming the robotic system, and other value-added activities.

- Improved efficiency and safety: The implementation of the robotic cell improved overall efficiency in surface preparation operations. The automated process reduced cycle times, minimized material waste, and enhanced workplace safety by eliminating exposure to hazardous substances associated with manual surface preparation methods.

In conclusion, the adoption of a turnkey robotic solution based on the

Jaka robotic arm brought about transformative improvements for our client. By

automating the surface preparation process, the company achieved increased

productivity, stability in product quality, and enhanced workplace safety.

Moreover, the robotic solution facilitated the transfer of demanding tasks from

manual labor to robotic automation, optimizing resource utilization and

enabling personnel to focus on higher-value activities. Overall, the

implementation of robotic technology has positioned our client for greater

efficiency, competitiveness, and success in their industry.

Tecnostamp Triulzi