RI WD Collaborative closed dual welding station

RI WD Collaborative closed dual welding station

Closed Dual Station Welding System (Grounded) – Boost Production Efficiency

Configuration: inverted robot (2.7 x 1.9 x 2.4m)

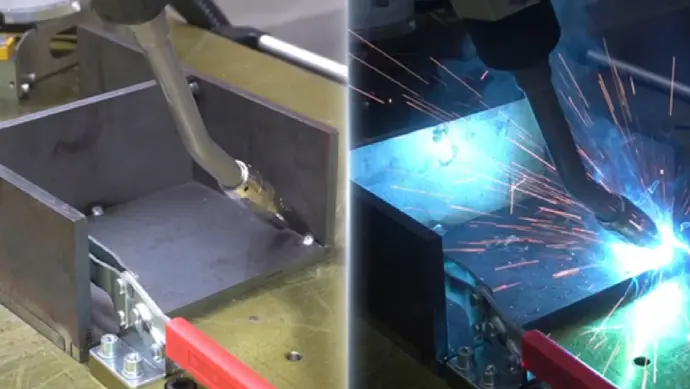

Optimized Applications:

- Continuous welding of medium/thick steel plates

- Double-sided welding for automotive chassis components

- Production line cycle time (beat) improvement

Key Advantages:

- Dual Station Productivity:

Human-robot alternating operation doubles output

→ Reduces production cycle time by 35% - Seamless Human-Machine Collaboration:

Synchronous welding operations without interference

→ Enhances manufacturing flexibility & production efficiency

FULL WELD TYPE IS UNIVERSAL

Simple and complex welding is easy to deal with!

- Customizable oscillation patterns

- Multiple waveform configurations

- Intelligent bead control systems

- Effortlessly handles complex welding tasks

- Compatible with varying material thicknesses

- Reduces process changeover time by up to 40%

- Maintains consistent quality across joint types

Key Operational Benefits:

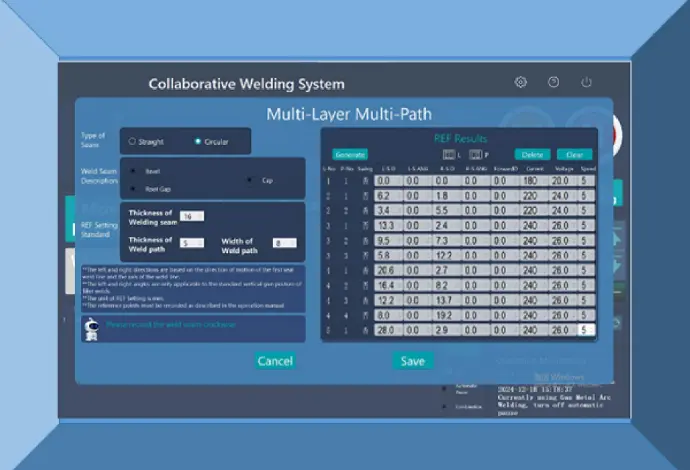

AUTOMATIC INTELLIGENT WELDING SEAM ARRANGEMENT

Parameters are customizable

- Automated layering for straight/arc/fillet/groove welds

- Customizable parameters: weld spacing, swing amplitude, bevel angle

- Supports automatic & manual routing of multi-layer passes

- AI-driven bead planning through key parameters

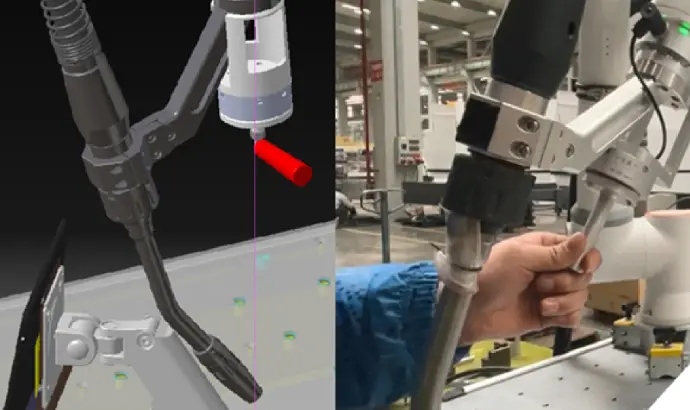

SIX DIMENSION TECHNOLOGY

Foldable handle

- Direct trajectory calibration via foldable handle

- Operator physically guides arm for instant path setup

Core Technology:

±0.05mm Positioning Accuracy

*Equipped with high-resolution 6-axis F/T sensor for micro-adjustments*

Revolutionary Operation:

Zero-Programming "Drag & Teach"

Critical Applications:

Complex curved surfaces

Narrow-space welding operations

Restricted-access joint configurations

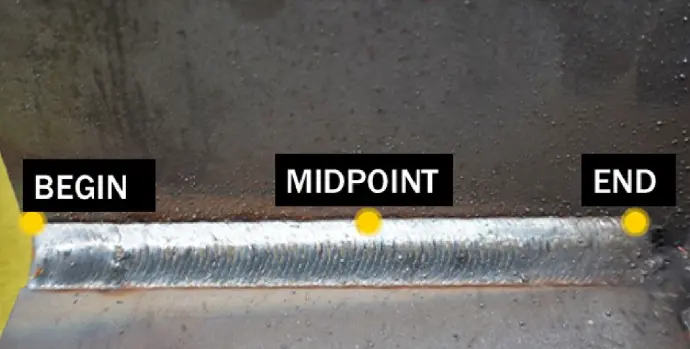

INTELLIGENT WELD PLANNING

- Three-point positioning system for medium/thick plate welding

- Automatic bevel error compensation for consistent quality

GUN POSTURE SELF COMPENSATION TECHNOLOGY

- Real-time automatic adjustment of gun angle/offset

- Patented algorithm ensures optimal positioning (±0.05mm repeatability)

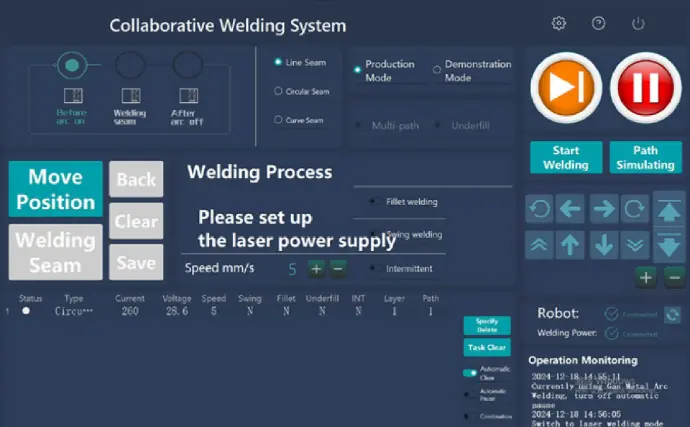

HUMAN COMPUTER COLLABORATIVE OPERATING SYSTEM

- One-Click Standard Welding: Rapid small-batch repetitive tasks

- WPS Standardization: Create/reuse certified Welding Procedure Specifications

- Material-Specific Libraries: Pre-optimized parameters for:

- Carbon steel

- Stainless steel

- Aluminum alloys

OD16 level safety cabin

- Arc protection: Double-sided explosion-proof observation windows, allowing for real-time monitoring of the welding process and timely understanding of the operation status.

- Smoke and dust purification system: Effectively eliminates welding smoke and dust, keeping the air in the welding room fresh.

- External emergency stop safety button: One click shutdown in case of emergency to ensure personnel safety.

Panoramic visualization design

Ergonomic Perspective: Optimized with a 15° tilt angle for the control panel, standing/sitting posture conforms to ergonomic design.

Welding machine status window: Built-in high-definition high-temperature resistant glass, real-time monitoring of arc stability and wire feeding mechanism action.

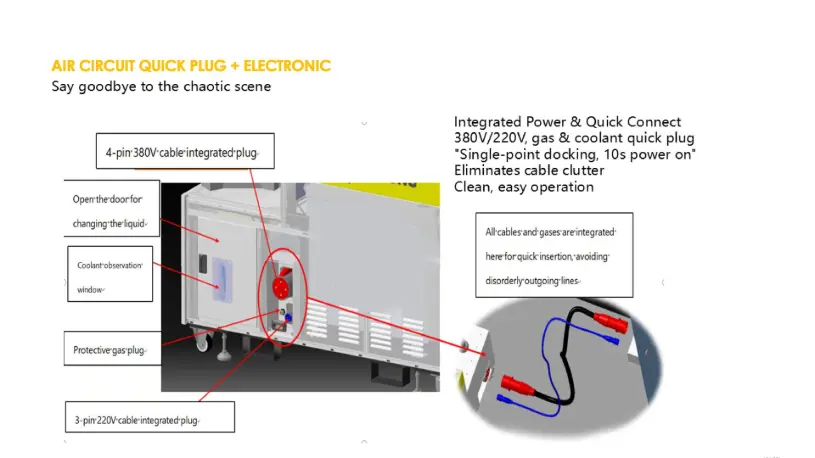

Coolant observation window: With scale markings and level sensor.

To install this Web App in your iPhone/iPad press

![]() and then Add to Home Screen.

and then Add to Home Screen.