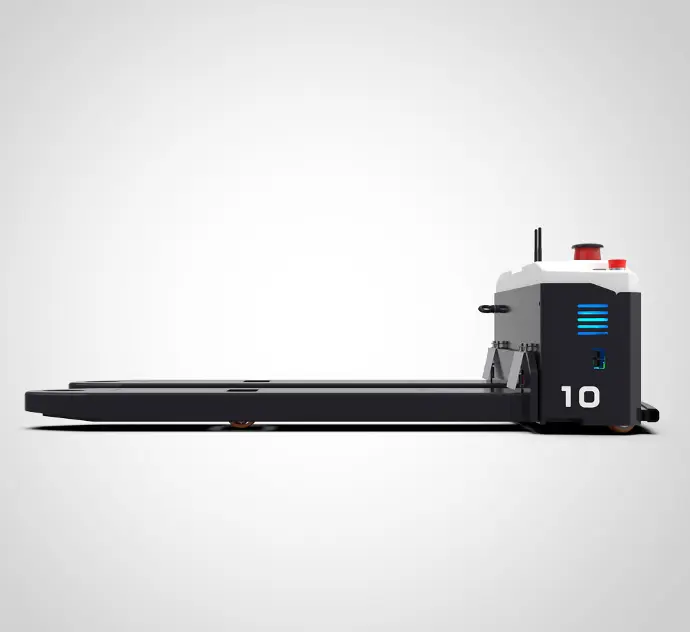

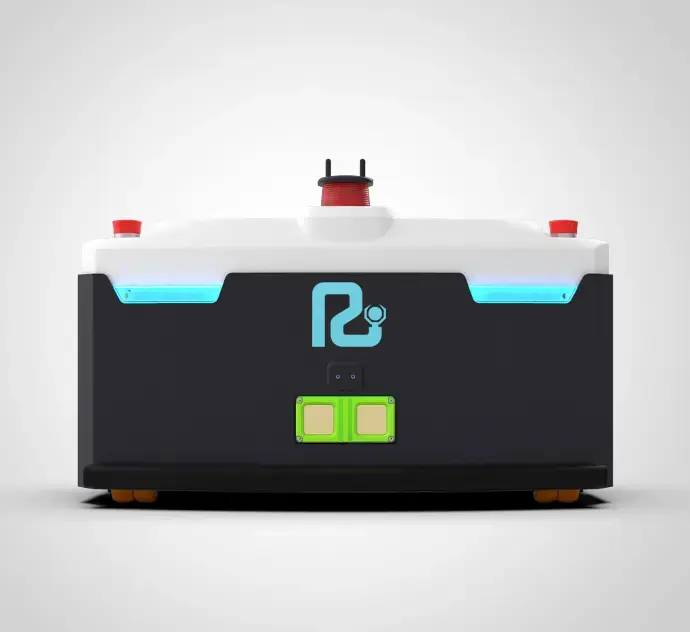

Robot Industries RILOG1000155/165 handling robot

Robot Industries RILOG1000155/165 handling robot

The Robot Industries RILOG1000155/165 handling robot is a state-of-the-art narrow aisle handling robot, ideal for a wide range of material handling processes. This mini laser navigation and handling AGV (Automated Guided Vehicle) is designed to operate efficiently in various environments, including those with narrow aisles.

Key Features:

- 360° Rotation Capability: The Robot Industries RILOG1000155/165 handling robot can rotate 360° in place, allowing for exceptional maneuverability in confined spaces.

- Mini Laser Navigation: Equipped with advanced SLAM algorithm laser guidance, the MP10S ensures precise navigation and positioning with an accuracy of ±10mm.

- Narrow Aisle Operation: Capable of navigating aisles as narrow as 1.8 meters, making it a hot-selling product throughout the season.

- Safety Devices: The vehicle body is equipped with safety devices such as anti-collision edge strips to ensure safe operation.

Robot Industries

Robot Industries is a leading distributor and integrator of robotic solutions, specializing in providing cutting-edge automation technologies for various industries. With a focus on delivering high-quality products and services, Robot Industries ensures that businesses can seamlessly integrate advanced robotics into their operations to achieve greater efficiency, safety, and profitability.

Logistics Automation with

Robot Industries RILOG1000155/165 handling robot

Increased Efficiency: Handling robots like the Robot Industries RILOG1000155/165 handling robot can significantly increase operational efficiency by automating repetitive tasks and reducing the time required for material handling.

Enhanced Precision: With precise navigation and positioning, these robots minimize errors and ensure consistent performance.

Safety Improvements: Robots are equipped with advanced safety features to prevent accidents and injuries, creating a safer working environment.

Cost Savings: Automating material handling processes can lead to substantial cost savings by reducing labor costs and increasing productivity.

Flexibility and Scalability: Handling robots can be easily integrated into existing systems and scaled up or down according to the needs of the operation.

24/7 Operation: Robots can operate continuously without the need for breaks, enhancing productivity and ensuring uninterrupted workflow.

The Robot Industries RILOG1000155/165 handling robot is available with fast delivery worldwide.

The Robot Industries RILOG1000155/165 handling robot is highly versatile and can be effectively utilized across various industries and businesses. Here are some of the key sectors where this robot can bring significant benefits:

- Warehousing and Distribution Centers:

- Efficiently handles the movement of goods within warehouses, optimizing storage and retrieval processes.

- Ideal for narrow aisle operations, maximizing storage space utilization.

- Manufacturing:

- Streamlines the transportation of materials and components between different stages of the production process.

- Enhances productivity by automating repetitive handling tasks.

- Retail and E-commerce:

- Supports order fulfillment processes by efficiently transporting products from storage to packing and shipping areas.

- Helps manage inventory and restocking in large retail environments.

- Automotive Industry:

- Assists in the internal logistics of automotive manufacturing plants, transporting parts and assemblies.

- Improves efficiency in just-in-time (JIT) production environments.

- Pharmaceutical and Healthcare:

- Automates the movement of medical supplies, pharmaceuticals, and equipment within hospitals and manufacturing facilities.

- Ensures precise and timely delivery of critical items.

- Food and Beverage:

- Facilitates the handling of raw materials, packaging, and finished products in food processing and beverage manufacturing plants.

- Maintains hygiene standards by reducing human contact with food products.

- Electronics and High-Tech Industries:

- Manages the transportation of delicate components and finished electronic products with high precision.

- Supports cleanroom environments by minimizing contamination risks.

- Third-Party Logistics (3PL) Providers:

- Enhances the efficiency and accuracy of logistics services offered to clients.

- Supports a wide range of handling requirements for different types of goods.

By integrating the Robot Industries RILOG1000155/165 handling robot Handling Robot into their operations, businesses in these industries can achieve significant improvements in efficiency, accuracy, and safety, ultimately leading to higher productivity and cost savings.

To install this Web App in your iPhone/iPad press

![]() and then Add to Home Screen.

and then Add to Home Screen.